3D CAD models are ideal communication vehicles for complex issues. EPC contractor Pörner uses UniversalPlantViewer for efficient internal coordination and for professional presentations to clients, and benefits from six-digit savings.

Is there a fourth industrial revolution in the EPC business? From the point of view of technological progress: Of course, because the now available new technologies hold great potential. On the other hand, the adaption of technology tends to be smooth, evolutionary rather than revolutionary. As a consequence of its deployment and the simultaneous compelling introduction of end-to-end IT-supported processes, however, the likelihood is high that radical changes will affect all the different parties collaborating in capital projects, such as EPC contractors, owners/operators, supply chain, and financing institutions. Thus we can speak also in the EPC business of the dawn of a new era. The Pörner Group based in Vienna, Austria, has recognized this, and already five years ago launched the initiative ‘Anlagenbau 4.0’ completely analogous to Industry 4.0 scenarios. With Plant Engineering 4.0, Pörner, an independent engineering and consulting firm with an adaptable engineering structure, the combined outstanding expertise of more than 500 engineers as well as decades of international experience, achieves a decisive lead in the industrial plant erection business. Anlagenbau 4.0 stands for Pörner’s mission, that is to use the most modern means available (visualization techniques, systems, components, automation) to holistically plan, design and realize together with its clients some of the most productive facilities in the world:

- Development of individual projects (‘FEED by Pörner’) in close cooperation

with the client - Professional and flexible project management (planning, procurement,

construction, and commissioning) - In-time and on-budget completion of the entire process plant.

Many references of new plants and revamps prove that Pörner continuously delivers what is crucial for the success of each project (see also text box).

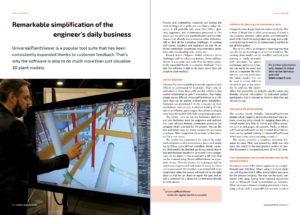

In the analysis of observations from other industries, in learning from experience or best practices in use cases beyond the characteristics of EPC, one aspect always comes to the table: The orchestration of different opinions of how to solve a challenging problem and how to bring transparency into decision-making. Because “In the rush of the battle, misunderstandings can easily arise when there is deadline pressure during project execution, and this is often the case,” explains Thomas Hermann, Head of Piping Design and responsible for the strategic development and harmonization of entire CAD infrastructure at the Pörner Group. The EPC uses UniversalPlantViewer (UPV) from CAXperts GmbH (Ismaning near Munich, Germany) for interdisciplinary decision-making with remarkable success. But what makes this CAD viewer so unique? No doubt, 3D models allow all project stakeholders to intuitively understand the context of status changes within a design and clashing conflicts more quickly, enabling them to visualize the impact of additional information, e. g. the context of surrounding assets. A truism is that CAD applications are expert tools that cannot be used efficiently by occasional users. That’s why over the years, CAD viewers have been established that focus on inspecting 3D models and documentation capabilities for meetings. Although some of these are available free of charge, either as open source or proprietary software, a veritable market for commercial software solutions has been established owing to their importance. The difference in the range of functions offered and the associated costs is enormous, as Thomas Hermann also knows only too well: “In our group, we use all the leading CAD solutions for plant design, such as the Smart 3D from Hexagon/Intergraph, PDMS and E3D from Aveva, Autocad Plant from Autodesk, or Tekla from Trimble Solutions. And thus, the corresponding viewers such as Smart Review, PDMS Viewer or Navisworks are all available in-house. But we realized that we are still in need of an additional CAD viewer that could display all our 3D models, e. g. in a merged manner.” This is an interesting statement and at the same time a surprising recognition. Nomen est omen: The ‘U’ of UPV stands for ‘universal’, expressing the ability to integrate a broad range of plant data. “We face the challenge that each of our clients uses different tool standards. And the related CAD viewers could never really be operated well because each of them is always a little different to the other – and a certain functionality is always missing.” Further requirements for the CAD Viewer were that it should be web-compatible and that the virtualization of 3D CAD workstations should be possible via Citrix. “The goal is to be able to view the entire project together with a single viewer, even if the stakeholders are working at different locations.” This problem has now been solved with the implementation of UPV, which is really easy to use, as Mr Hermann points out, adding: “I was really surprised how quickly and smoothly UPV was implemented.”

Cross-site project review

At Pörner a lot of work is done with Citrix, for example projects are reviewed from different sites via Citrix. Therefore, Citrix capability is a must for the new CAD viewer. Moreover, UPV’s batch job functionality is gladly taken: “UPV is configured in such a way that all data is gathered overnight, so an up-to-date project status is available by the next morning,” Mr Hermann says, proceeding: “This alone is a big advantage because in this way the different departments, such as piping, civil, structural, and I&CS have access to a common, daily updated 3D model and thus can coordinate themselves very efficiently.” Even Office documents and PDFs can be depicted, or further data called up via links, for example isometrics of certain pipelines. The viewer is ideal for all stakeholders because, after just ten minutes of training, it allows them to inspect 3D models. And the response times are short. “Even our largest plants are visualized without any compromise on performance.” For the design review process, Mr Hermann’s team has written several plug-ins themselves: Pörner’s customized UPV accesses a central folder where the project team stores their data. These are then merged in batch mode according to predefined rules. “We clearly benefit from the open system architecture of UPV,” Mr Hermann says, summing up, and points out the necessity: “Especially in project handling there is an increased need for communication because sometimes very different views are held. If these ideas are discussed based on a 3D model, this is worth more than 1 000 words! It makes it so much easier to understand how a proposal was actually meant.” Required locations or interfering edges can be clearly communicated to the responsible 3D CAD designer and also documented: “Everything can be recorded exactly, that is who planned what and when. Moreover, UPV ensures that each department can continue working with the CAD standard it is accustomed to.”

The way in which data can be presented to client is inspiring. “It’s quite common not to have permission to take our laptop with us to the client on account of data security restrictions. With UPV, this is not even necessary, because nothing has to be installed on site,” explains Mr Hermann. You can either access your own server via Citrix and the Web or keep the entire data set on a protected USB stick for viewing. In the latter case, UPV simply comes with the external storage medium and is started up from there. Different design variants can be displayed in different colors and their assessment recorded during a meeting. In addition, sketching tools provided by UPV offer the possibility of capturing new proposals in the 3D model. Of course, mark-up functions are also available. A further advantage is the special support of the customer experience: With UPV, the company logo can be faded in, which is not so easy to display in other CAD viewers – before the 3D model is started, the client first sees the Pörner logo – Mr Hermann likes that because this simply makes it something special! Of course, the clients have noticed the smooth handling and are impressed with this, too. Now they are seriously considering the purchase of this CAD viewer, so great is their enthusiasm – CAXperts will be pleased!

“At Pörner, we use all the leading CAD solutions for plant design, and thus, the corresponding viewers such as Smart Review, PDMS Viewer or Navisworks. But we realized that we are still in need of an additional CAD viewer, namely UniversalPlant- Viewer from CAXperts, that could display all our 3D models, e. g. in a merged manner.”

Thomas Hermann, Pörner

Why UniversalPlantViewer?

The vendor reacts immediately to questions and requests in dealing with UPV. For example, software bugs are very quickly eliminated, as our interview partner assures us. Moreover, the CAXperts team is open to suggestions for improvement. Mr Hermann misses this willingness to talk from the other large vendors. “They are resistant to advice. It’s not uncommon for a year or two to go by before a request for improvement is actually implemented,” says the CAD expert behind closed doors, adding: “In the case of CAXperts, adjustments are implemented within a few weeks!” Therefore it is no wonder that other viewers currently being replaced with UPV at individual sites. Another benefit is the fact that CAXperts has a very attractive licensing model with one license for the whole Pörner Group. Mr Hermann says that the goal is to firmly anchor UPV within the workflow of the project review. The CAD manager is in no doubt that this is worthwhile, because “the group-wide roll-out is associated with savings in the six-digit euro range and the ROI for UPV is achieved in less than twelve months.” So, what more do you want? At the moment, 80 users are using UPV productively at the Vienna site. 200 employees are expected to work with UPV when the roll-out is complete. And, no doubt, the UPV’s excellent performance on mobile devices such as smartphones or tablet PCs will further boost Pörner’s digitization strategy. (bv)