Detailed data quality check

QualityAssuranceModule provides you with a powerful data check system for users such as Project Information Managers, Project Engineers, and Application Power Users

Quick data checks

Detailed quality check (e.g. checks for missing or wrong attribute values, incorrect tags etc.) for data coming from a single application.Fast and easy QA reports

Generate rule based colour coded reports in Microsoft Excel format.

PDF creation (for P&ID)

Save SmartPlant P&ID documents as PDF files where objects which do not comply with the rules are highlighted or marked up.

Quick and simple way to ensure data quality

Engineering companies need to handle and oversee many different software applications and a variety of data. The QualityAssuranceModule is a fast and easy way to ensure data consistency and compliance with individual rules and best practices. It comes with an easy-to-use interface for the creation of rules for different applications. It also increases the efficiency of your workflows as you are able to provide contractors or other departments with the results of the data checks.

Powerful and fast data check

- Audit data with company specific rules (colour coded spreadsheets)

- Verify data quality before loading into enterprise systems or handover to the client

Use Cases

Explore the possibilities

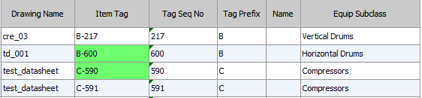

Check syntax of SmartPlant P&ID tags

Challenge

It is always a challenge to keep track of all tags and whether they apply to the naming convention which is mandatory for the project. Users can often make mistakes when they key in the different tag attributes.

Solution

The QualityAssuranceModule makes it easy to identify the equipment tags which are not compliant with the naming convention; these tags can be exported to an Excel report

This type of report can be handed out to the contractors (or to other in-house departments) with the goal being to have the data reworked, so that it complies with the rules

- Extract source data from SmartPlant P&ID using PID ReportAdapter

- View data in the QualityAssuranceModule and apply the rule to check the tag’s tag-rule: “Tag must start with a character; plus the TagSequenceNumber must be numeric and three digits long, for the last digit 0 is not allowed.”

- Create Excel report from the QualityAssuranceModule

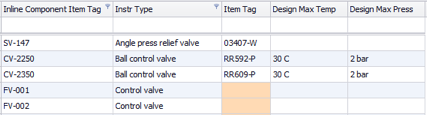

Check if flow elements and control valves are associated to pipe runs

Challenge

It is always a challenge to check whether all inline elements (such as flow elements and control valves) have the correct tag number and if they are associated to a pipe run.

Solution

- The QualityAssuranceModule makes it easy to identify the tags which are not compliant with the naming convention, or to identify tags that have no association to e.g. pipe runs.

- This type of report can be handed out to the contractors (or to other in-house departments) with the goal to have the data reworked so that it complies with the rules

- Extract source data from SmartPlant Instrumentation using SPI ReportAdapter

- View data in the QualityAssuranceModule and apply the rules to check the inline elements:

- Rule 1: “Tag is not allowed to contain a dash followed by one or more blanks”

- Rule 2: “If Tag starts with ‘FE’ or ‘FV’ then the LineNumber should not be Null”

- Create Excel report from the QualityAssuranceModule

Tutorial

Learn more about the QualityAssuranceModule

By loading the video, you accept YouTube's privacy policy

Learn More

Interface

By loading the video, you accept YouTube's privacy policy

Learn More

Export Excel

By loading the video, you accept YouTube's privacy policy

Learn More

Show Graphics

Frequently Asked Questions

The QualityAssuranceModule checks the complete dataset against the specified rules; the results can then be provided to the departments/contractors who are the owners of the data.

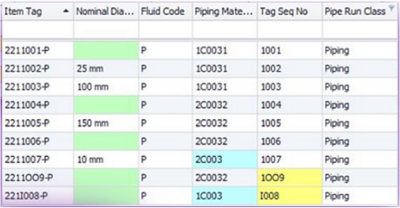

The P&ID datasets extracted with PID ReportAdapter contain an attribute called “NotConnectedRuns” which displays the number of disconnected pipe run segments having the same item tag. In this way pipe runs can be easily identified saving a significant amount of time compared to manual checks on the drawing level.

Instead of random checks done manually, you can now run a complete check on the whole dataset. This increases the data quality and integrity. Also, the users can focus on high-value tasks instead of low-value tasks, thus increasing productivity.

Adapters

Use suited adapters

ReportAdapters make the connection to the authoring database and extract data into a snapshot which is used by the QualityAssuranceModule.

ReportAdapters are available for the following Intergraph applications:

- SmartPlant P&ID

- SmartPlant Electrical

- SmartPlant Instrumentation

- SmartPlant 3D

- PDS

In addition any Access database file can be accessed by the QualityAssuranceModule and also Excel files can be converted easily so that the content is visible in the QualityAssuranceModule.

Get started

Try or buy

QualityAssuranceModule adds value to your organisation.

Try it out now. Request a free demo-licence

or

Purchase/Lease licences – we will find the best pricing model for you

Please contact us for either option at the CAXperts office.