To spread the use of intelligent 3D models as a construction management tool, Techint E&C facilitated their access to all users, even non-experts, through CAXperts UniversalPlantViewer (UPV) software.

Techint E&C provides engineering, supply, construction, operations, and management services for large-scale projects globally. Thanks to its multi local presence, it is capable of developing competitive and sustainable solutions from the design stage to commissioning, complying with the highest quality and safety standards, caring for the environment, and promoting the well-being of the communities in which it operates. With more than 75 years of experience, the company has successfully completed more than 3,300 projects in compliance with international ISO / BS / OHSAS standards in the Americas, Europe, the Middle East, and Africa. Currently, it operates in the following market segments: oil & gas, energy, industrial plants, oil refineries and petrochemical plants, mining, civil infrastructure works and architecture.

Massification of the 3D model use

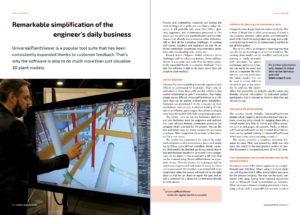

Intelligent 3D models at Techint E&C are a solid management tool, but until recently navigating and performing activities on them was limited to users with specific knowledge and sophisticated computer equipment. To transform this situation, two years ago, the innovative initiative “Democratization of the 3D Model” was started. Specifically, it seeks to spread the use of the intelligent 3D model as a management tool on site so that any user – being from Operations, Quality, Planning & Control, or other areas – can navigate through the models autonomously and no matter what computer equipment they have. This is achieved through UPV, which is currently implemented in the projects of thermoelectric plants in Brazil, mining in the Andean region (Peru and Chile), Oil & Gas refineries in Mexico, among others, with more than 300 users using it.

Alejandro Maluf, Regional Director of the Northern Area of Techint E&C, considers that UPV allows us “as an organization to grow since we can access extremely useful information in real time and in a more generalized way”. In addition, he is very confident that “our designs can become

more powerful from the moment they become easily available and understood by our engineers, technicians, supervisors and foremen”. The software has the great advantage of facilitating the navigation of the models, in an agile and intuitive way, allowing –in addition– to search, isolate, highlight objects or sets of them, such as mechanical equipment, piping line elements, metallic structures, etc. Viewing the status and progress reached on the construction site is another benefit of use. Regarding construction status, the tool allows highlighting by using different colors – for example, in red if the assembly/erection of an object is behind schedule, in yellow if it is being prefabricated or green if it is being mounted.

UPV: more about this tool

Until now, the visualization of the model on-site was done with another software that required high-performance computer equipment. But “UPV comes to cover this need in a much simpler way, since it seeks to make this tool a friendlier one so that all collaborators, even non-expert users, can use it in their daily activities”, explains Gustavo Rojas, Engineering Systems Manager of Techint E&C. “After several months of analysis and comparison between different software, we chose UPV, from the company CAXperts. It uses video game technology and allows you to view and navigate large plant models on any computer, no matter whether it is a desktop PC, laptop, or tablet. In addition, it has a very user-friendly interface”, he adds. “The UPV visualization application helped me a lot because, in addition to being updated daily, it is very easy to handle, giving a quick response to the request of the collaborators”, says Jovane Borges de Oliveira, Designer at Parnaíba V.

A competitive advantage during the pandemic

Since the beginning of COVID-19, many of the workers started doing remote work and the implementation of new digital tools has been rapidly accelerating in order to facilitate their activities. “Today with the massive home office, access to the models in the UniversalPlantViewer is essential, as they are lighter to use and open from anywhere. In addition, in the current context we are living in, new technologies will allow us to be more competitive”, says Rojas. “When doing 100% teleworking, we were able to have a practical tool that allows us to navigate through the 3D models of the project at any time in a simple way, without asking for help and without the need for special connectivity or a much more powerful PC”, explains Julio Comoglio, Project Manager in Peru. “It allows me to analyze the project as a whole, see the details of the progress, project changes and analyze details of constructability that before, being in person, required someone from the engineering staff or technical office to show me”.

“I am sure that this tool streamlines much time on projects and significantly reduces our environmental impact,” adds Maluf referring to the benefits of implementing intelligent 3D models and expresses with expectation: “We have taken a step forward towards a paperless format and in bringing the office closer to the field. I am confident that we will see more and more people consulting designs in the cloud from tablets, cell phones or workstations deployed on the construction site”.

Next steps

In the next implementation phase, new functionalities will be added, among which are 4D and geopositioning capabilities. These will make the view of the model correspond to the location of the person on the job site, allowing analysis of construction sequences and simulations. Innovation, technology, and expertise at the service of the most complex engineering and construction projects: an alliance that provides advanced solutions and tools for an increasingly efficient management.