Product Manager Siegfried Schott with CAXperts GmbH (Ismaning near Munich, Germany) on the day-to-day development challenges – and the success story of UniversalPlantViewer.

Mr Schott, does CAXperts still feel like a start-up?

I don’t think so, no. Next year CAXperts will be 20 years old …

… yeah, that’s true. There’s a lot going on in the software industry – always. How have the last two or three years gone? In the meantime, CAXperts has become more and more successful.

That’s right. I joined in 2012. At that time, it was our tenth anniversary, and the atmosphere of a start-up could still be felt in the rooms. At that time, our software was very much aimed at specialists. Except for one of our pro-ducts was a 3D viewer, based on the 3D PDF format …

… oh my goodness, how long ago that was!

Exactly. The problem with that was that our clients were always trying to load the next biggest layout into the viewer. We were really good at perfor-mance – I dare to say that no other vendor could visualize such large plants with 3D PDF as we could. But: There is always a larger chemical plant you want to look at. In addition, we had the impression that this format was un-fortunately not being developed enough further enough. We then shelved the 3D PDF.

Then we thought about what the next step could be. It was clear to us that the market for an intuitive viewer was definitely there. We finally de-signed a first prototype for the iPad. At that time, we already assumed that the future would belong to mobile solutions. We took it to an Intergraph user meeting in Las Vegas. After many discussions with customers and part-ners, we came to the conclusion that it would definitely also have to be a browser-based solution. But then there was the question of which tech-nology we should go for. We quickly realized that we would have to focus on Unity’s game engine as a plug-in. So, we started programming based on that. Unfortunately, a year later Google started blocking such plug-ins. Uni-ty, however, quickly responded to that.

I remember the day as if it were yesterday, when my team and I were standing in front of a flipchart, thinking about what hardware we could run the graphics on and what programming language we should write the logic in. Previously, this had been coded using JavaScript. We then decided to implement everything using Unity’s gaming engine …

… and? Was it the right decision?

Absolutely! But you have to admit that there was some luck involved.

Since you had to start from scratch, if you like, CAXperts became a start-up again.

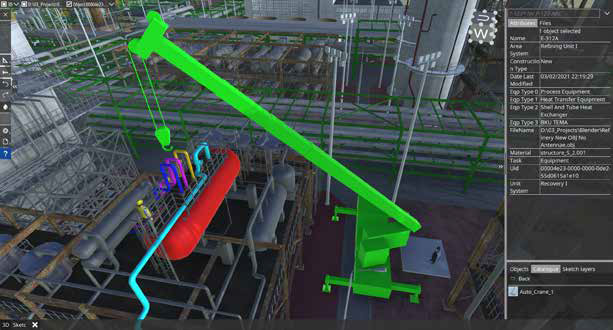

Yes, in that respect. The advantage, of course, was that we were able to build on a fairly large client base. Our clients solved problems all over the world with our tools, and we received a lot of positive feedback with the new solution. Around 2016/17, we really took off with the UniversalPlantViewer (UPV). UPV is widely used in our industry due to its tremendous speed and multiple functions.

Looking back, the last big step was in 2019 when Unity made a WebRTC protocol available for streaming. Similar to Google with Stadia or Nvdia with the Shield Controller, graphical content no longer had to be kept under the table in a workstation, but could be centrally offloaded to a server. Only the controller still runs on the PC or mobile device. With this technology, UPV scales even better, for example when point clouds from laser scans come into play.

What trick do you use for this?

The user only gets the data blocks on his front-end that are needed for the display. What immediately sur-rounds the point of interest is displayed in high reso-lution. Details of a scene that are, say 100 m away, are visualized with only a few polygons. Furthermore, we offer the possibility to download scenes locally to the computer, for example to be able to work on the con- struction site without WLAN.

How does CAXperts support the representation of the digital twin of an industrial plant or piece of infrastructure?

This often requires environmental data around the planning situation, usually in the form of laser scans. Here, too, we see ourselves as a technological leader. We have implemented a procedure so that we no lon-ger have to work with the individual laser scan points, but instead place triangles over the cloud in the form of a grid mesh. Surfaces are projected onto the grid mesh so that surface-based 3D bodies become recognizable.

What reduction factor do you achieve in this way?

With this innovation, we are able to compress down to 1 % of the original volume of data. The advantage of meshing is that you can jump to any point in the scanned area and are not limited, as is usually the case, to having to view a scene from the point where the scanner had been standing.

The user interface of the UPV is also always highly prai-sed. Why actually?

There’s a very simple answer: We just know what’s im-portant. Our team comes from industry practice and has had to struggle with other CAD viewers. We stand for ‘simplicity’, which is why our CEO Peter Schlegel always insists that things must be even simpler. Thus, in the current version 6, we have deliberately not introduced any new functions, but have intelli-gently combined existing ones that were previously scattered in various menus. Although we have moved buttons, clients are very happy with this, especially since the user inter-face has been slimmed down consi-derably. You have to know that we are always navigating the dilemma of implementing more desired func- tions, while trying not to increase the complexity in the user guidance at the same time.

And what can users expect in the future?

We have made a programming in-terface available for our viewer technology so that it can be integ-rated into other software. There is a lot of very good software on the market, but their output cannot be linked to 3D plant models. This is now possible, for example meta- information directly linked to the localized 3D representation of a pump in space. A use case could be like this: You know that a valve has to be replaced in the coming week. This is located at a height of 5 m. If you have to set up scaffolding anyway, you can use the 3D model to find out in advance where other components are located in the vici-nity that might need to be replaced at the same time.

I’ve got it, that makes sense! Thank you very much for the interview!

Interview: Bernhard D. Valnion